Monday, August 9, 2010

Thursday, August 5, 2010

And there you have it a Reverse Brick Veneer Wall with window scaled down for convenience.

There was some tricky placement for the plastic sheet window, after nailing in the lasting of the MDF cladding we trimmed off the window with strips of MDF to give it a better seal for the water test.

A plastic sheet was used for the window instead of perspex, generally because it was easier to source and more manageable.

For the cladding we ended up buying a 5mm sheet of MDF and cutting it into strips about 200mm wide and had them over lapping by about 20mm.

Once we completed the masonry wall we needed to wash away the cement that fell on the pavers before it dried (crappy stuff to get on anything). Insulation was to follow next, but unfortunately none of us actually took a photo so imagine old pillows for insulation in the space between the brick wall and what is soon to a weatherboard cladding wall.

800mm x 85mm x 75mm brand new flat bar lintel in action.

The cement we purchased didn't seem to have enough sand in the mix, so I thought it was rubbish and probably would purchase the mixture separately and measure in the parts myself next time, I think you would get a better result.The lintel held soundly for the next row of bricks.

After the mortar had cured enough we were able to cement in the steel flat bar lintel so we could bridge the opening for the window.

Phase one completed we left the mortar to cure for a few days before commencing with the rest of the wall.

Before going any further with the bricks we allowed time to let the mortar set so the lintel that will support the next row of bricks will be consolidated more efficiently. So the rest of the timber framing around the opening could be erected in the mean time. Plus a couple of angel brackets were added for extra support at the bottom of the frame.

Now comes the tricky part of creating an opening for the window, this requires some skill to keep the wall plumb.

As you progress with laying the bricks you need to incorporate brick ties for extra structural support for lateral forces. We used galvanized angel bracket for this exercise because no water will be penetrating the weather board external wall, so you didn't need the regular brick ties.

As you progress with laying the bricks you need to incorporate brick ties for extra structural support for lateral forces. We used galvanized angel bracket for this exercise because no water will be penetrating the weather board external wall, so you didn't need the regular brick ties.

Wednesday, August 4, 2010

Once you got your mortar ready its time to lay a bed of cement down to place your first row of bricks. For real accuracy you really need a spirit level but we didn't have one so the trusty string line had to do.

Once you got your mortar ready its time to lay a bed of cement down to place your first row of bricks. For real accuracy you really need a spirit level but we didn't have one so the trusty string line had to do.

Next the cement was mixed with water to give us a nice mud to adhere the bricks. You don't want the mud to dry or wet otherwise it very hard to work with. Its almost like making a bread mix, where you make a well in the centre so the liquid doesn't go every where and also you don't need a container as well.

Next the cement was mixed with water to give us a nice mud to adhere the bricks. You don't want the mud to dry or wet otherwise it very hard to work with. Its almost like making a bread mix, where you make a well in the centre so the liquid doesn't go every where and also you don't need a container as well. The timber frame needed to be erected first so the masonry wall had structural support. This will allow you to level the wall off from the frame with the string to give you a plumb wall all the way up.

The timber frame needed to be erected first so the masonry wall had structural support. This will allow you to level the wall off from the frame with the string to give you a plumb wall all the way up.

Started off with a chipboard base to keep the mortar cement off my pavers(nasty stuff to get off).

Started off with a chipboard base to keep the mortar cement off my pavers(nasty stuff to get off).Next step was to prep the materials by laying them out ready to be assembled. Materials and tools used for the job were: Timber , bricks, brickies trowel, chisel, shovel, lug hammer leveling string, lintel ,cement, screws, nails and MDF boards.

Monday, August 2, 2010

We were able to score some second hand bricks from a company in West Melbourne called 'Paddy's bricks' the owner was very helpful. When I was there, around the back is a huge yard with piles of bricks and 3 blokes sitting down chipping away the mortar. Tough going. The rest of the materials were sourced from Bunnings to save time.

We were able to score some second hand bricks from a company in West Melbourne called 'Paddy's bricks' the owner was very helpful. When I was there, around the back is a huge yard with piles of bricks and 3 blokes sitting down chipping away the mortar. Tough going. The rest of the materials were sourced from Bunnings to save time.

Friday, July 16, 2010

Here is the second phase of construction, with the addition of Jack studs, Noggings, Lintels, trimmers and insulation. Brick ties will be laid in the mortar to give the Masonry wall more stability. Also top plates and bottom plates complete the timber wall frame. The timber frame is the only structural support for the roof (even tho a roof will not be added) and masonry wall.

Here is the second phase of construction, with the addition of Jack studs, Noggings, Lintels, trimmers and insulation. Brick ties will be laid in the mortar to give the Masonry wall more stability. Also top plates and bottom plates complete the timber wall frame. The timber frame is the only structural support for the roof (even tho a roof will not be added) and masonry wall.

Tuesday, July 13, 2010

Tuesday, June 15, 2010

Sunday, May 16, 2010

Here are the next installments of the Sketchup model with the additions of a window and insulation. The first illustration is a kind of section outlining the different components, Red: Studs, Yellow: Noggins, Blue: Cripple Stud, Pink: Sill trimmer, Purple: Jack Studs, Cyan: Lintel, Green: Top & Bottom plate, plus the timber window and Styrofoam insulation The bottom illustration is a more complete look of the current stage. The brick component has no structural relevance what so ever, it is mainly concerned with the thermal mass qualities such as R-values, more about that later,

The bottom illustration is a more complete look of the current stage. The brick component has no structural relevance what so ever, it is mainly concerned with the thermal mass qualities such as R-values, more about that later,

Took a trip to Bunnings Warehouse today to look at which materials are available and discovered the variety was lacking so might try and find a second hand building materials outlet in the local area instead to source materials.

Took a trip to Bunnings Warehouse today to look at which materials are available and discovered the variety was lacking so might try and find a second hand building materials outlet in the local area instead to source materials.

Next installment will include cladding and how to achieve a water proof finish...

The bottom illustration is a more complete look of the current stage. The brick component has no structural relevance what so ever, it is mainly concerned with the thermal mass qualities such as R-values, more about that later,

The bottom illustration is a more complete look of the current stage. The brick component has no structural relevance what so ever, it is mainly concerned with the thermal mass qualities such as R-values, more about that later, Took a trip to Bunnings Warehouse today to look at which materials are available and discovered the variety was lacking so might try and find a second hand building materials outlet in the local area instead to source materials.

Took a trip to Bunnings Warehouse today to look at which materials are available and discovered the variety was lacking so might try and find a second hand building materials outlet in the local area instead to source materials.Next installment will include cladding and how to achieve a water proof finish...

Thursday, May 13, 2010

I've started to build a 3D model of the 'reverse brick veneer' wall construction on sketch up so we can finally get an idea what we're trying to construct. I'll keep posting images as I go along, there's a possibility that the wall will go through some changes as problems pop-up. So far here's the timber frame wall plus rafters and fascia board with the brick wall sitting 50mm behind the frame to allow for ties so the timber frame can support it. Next will be insulation and window.

I've started to build a 3D model of the 'reverse brick veneer' wall construction on sketch up so we can finally get an idea what we're trying to construct. I'll keep posting images as I go along, there's a possibility that the wall will go through some changes as problems pop-up. So far here's the timber frame wall plus rafters and fascia board with the brick wall sitting 50mm behind the frame to allow for ties so the timber frame can support it. Next will be insulation and window.

Friday, March 26, 2010

Excerpts from Green Magazine Issue 12

The following text was taken from "Green Magazine" Issue 12 2010, from the article "Nicely Clad" by Jane Riley.

The outer skin of a house not only protects its interior and defines its aesthetic but, chosen correctly, forms a crucial part of its sustainable properties and on-going operational efficiencies.

An efficiently run house - where thermal comfort is achieved with no (of minimal) additional heating and cooling systems - is a green one.

"We often use reverse brick veneer because it corrects the poor relationship that traditional brick veneer has to the environment". "Where traditional brick has all the thermal mass on the outside, reverse brick veneer places this internally, helping to regulate temperature highs and lows by bringing stability to the interior. It will keep you cool in summer and warm in winter."

Such cladding means you can have a timber-style home with the same thermal performance of a double-brick home. Using clay bricks , it has embodied energy, or with concrete block, low to medium. It has high thermal mass, low internal maintenance but potentially high external maintenance depending on the cladding. If not used for an entire house, it is especially good for north-facing rooms.

The outer skin of a house not only protects its interior and defines its aesthetic but, chosen correctly, forms a crucial part of its sustainable properties and on-going operational efficiencies.

An efficiently run house - where thermal comfort is achieved with no (of minimal) additional heating and cooling systems - is a green one.

"We often use reverse brick veneer because it corrects the poor relationship that traditional brick veneer has to the environment". "Where traditional brick has all the thermal mass on the outside, reverse brick veneer places this internally, helping to regulate temperature highs and lows by bringing stability to the interior. It will keep you cool in summer and warm in winter."

Such cladding means you can have a timber-style home with the same thermal performance of a double-brick home. Using clay bricks , it has embodied energy, or with concrete block, low to medium. It has high thermal mass, low internal maintenance but potentially high external maintenance depending on the cladding. If not used for an entire house, it is especially good for north-facing rooms.

Sunday, February 28, 2010

Friday, February 26, 2010

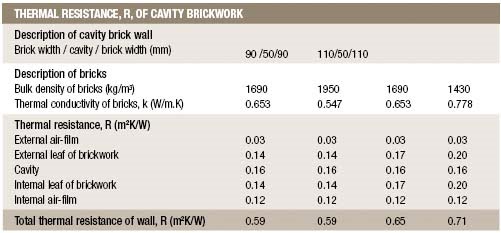

Thermal Mass

Clay brickwork has high thermal mass. If a building with internal clay brickwork walls and concrete

floors is subjected to a heating and cooling cycle that crosses the comfort zone, the brickwork and concrete will maintain a relatively stable level of heat energy for an extended period. In summer, they will remain relatively cool and winter, the same building will remain relatively warm. Link

floors is subjected to a heating and cooling cycle that crosses the comfort zone, the brickwork and concrete will maintain a relatively stable level of heat energy for an extended period. In summer, they will remain relatively cool and winter, the same building will remain relatively warm. Link

Subscribe to:

Posts (Atom)